Swiss VICTORINOX knives

Retail Price

Market price

Vacuum pump displacement: 16 m 3/h

Working cycle: 15-30 seconds

Vacuum chamber size (length × width × height):350 × 370 × 150 mm

Overall dimensions (length × width × height):550 × 440 × 420 mm

Equipment net weight: 49 kg

Working voltage: 230V/50Hz

Equipment power: 0.55 kW

Sealing size/number: 350mm /1

Classification:

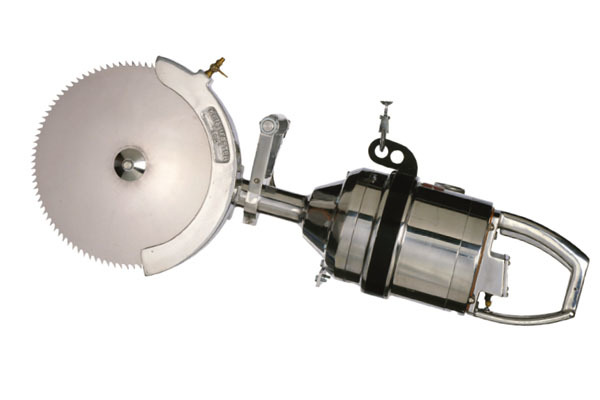

Cutter, saw blade and other consumables

Weight

Stock surplus

隐藏域元素占位

Product Description

Introduction of Swiss Vickers Cutter

1891 equipped the Swiss army with sabers for the first time;

1909 In order to commemorate the deceased mother, the company founder Carl named the company Victoria after his mother. In 1921, he ended with the abbreviation "inox" of "stainless steel". The brand Victorinox Vickers guaranteed that all tools were made of grade I stainless steel, and also provided a lifetime warranty for defects in materials and workmanship.

In meat processing, especially during slaughter, knives are used much more frequently than in the kitchen. According to the frequency of use, the service life of a boning knife is often only a few days. The better the quality of the blade steel, the fewer times it needs to be re-polished. The fewer the number of re-grinding required, the longer the blade can be used between the two shutdown grinding intervals, which can increase the processing time. Since the wear rate (mainly caused by grinding) is very low, the less the number of grinding, the longer the service life of the blade.

High quality stainless steel customized according to Vickers specifications

Carbon: high strength, wear-resistant, keep the blade sharp

Chrome: Corrosion resistant, highly polished

Molybdenum: acid and corrosion resistance

Tempering:

Reinforced Blade

Eliminate the internal stress or potential defects of stainless steel

Best Toughness

Rockwell hardness test between 55 and 59:

Achieving an ideal balance between knife hardness and toughness

Keep the blade sharp for a long time and easy to polish

Polishing greatly improves the nest corrosion resistance and rust resistance of stainless steel

Not affected by acidic substances, so easy to clean

Ergonomic design

Comfortable grip, non-slip when wet

Minimize fatigue caused by holding for long periods of time

Data prove that tenosynovitis can be avoided

Provides a natural fulcrum for the palm and fingers for more precise tool use

Safety guard

Fibrox handle extended safety knife and safety guard,

Makes the use of Vickers cutters better and reduces

The risk of being scratched by the blade during processing.

Made of polyamide

High abrasion resistance

Meet the highest international standards of food hygiene standards

Can be sterilized at up to 150 ℃

Injection molded directly on the blade

Thorough sealing, so that there is no gap between the blade and the handle

No residue accumulation or bacterial growth

Can be safely cleaned in the dishwasher

Key words:

- Product Description

-

- Commodity name: Swiss VICTORINOX knives

Introduction of Swiss Vickers Cutter

1891 equipped the Swiss army with sabers for the first time;

1909 In order to commemorate the deceased mother, the company founder Carl named the company Victoria after his mother. In 1921, he ended with the abbreviation "inox" of "stainless steel". The brand Victorinox Vickers guaranteed that all tools were made of grade I stainless steel, and also provided a lifetime warranty for defects in materials and workmanship.

In meat processing, especially during slaughter, knives are used much more frequently than in the kitchen. According to the frequency of use, the service life of a boning knife is often only a few days. The better the quality of the blade steel, the fewer times it needs to be re-polished. The fewer the number of re-grinding required, the longer the blade can be used between the two shutdown grinding intervals, which can increase the processing time. Since the wear rate (mainly caused by grinding) is very low, the less the number of grinding, the longer the service life of the blade.

High quality stainless steel customized according to Vickers specifications

Carbon: high strength, wear-resistant, keep the blade sharp

Chrome: Corrosion resistant, highly polished

Molybdenum: acid and corrosion resistance

Tempering:

Reinforced Blade

Eliminate the internal stress or potential defects of stainless steel

Best Toughness

Rockwell hardness test between 55 and 59:

Achieving an ideal balance between knife hardness and toughness

Keep the blade sharp for a long time and easy to polish

Polishing greatly improves the nest corrosion resistance and rust resistance of stainless steel

Not affected by acidic substances, so easy to clean

Ergonomic design

Comfortable grip, non-slip when wet

Minimize fatigue caused by holding for long periods of time

Data prove that tenosynovitis can be avoided

Provides a natural fulcrum for the palm and fingers for more precise tool use

Safety guard

Fibrox handle extended safety knife and safety guard,

Makes the use of Vickers cutters better and reduces

The risk of being scratched by the blade during processing.

Made of polyamide

High abrasion resistance

Meet the highest international standards of food hygiene standards

Can be sterilized at up to 150 ℃

Injection molded directly on the blade

Thorough sealing, so that there is no gap between the blade and the handle

No residue accumulation or bacterial growth

Can be safely cleaned in the dishwasher

Previous Page

Next Page

Related recommendations

Product Consulting

Provides you with a complete solution, ready for your choice