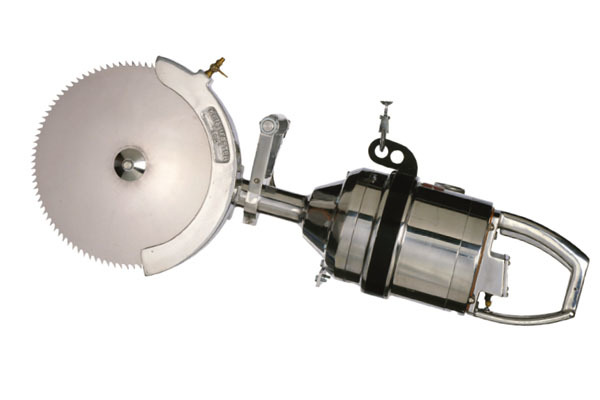

Special grindstone for slaughterhouse

Retail Price

Market price

Vacuum pump displacement: 16 m 3/h

Working cycle: 15-30 seconds

Vacuum chamber size (length × width × height):350 × 370 × 150 mm

Overall dimensions (length × width × height):550 × 440 × 420 mm

Equipment net weight: 49 kg

Working voltage: 230V/50Hz

Equipment power: 0.55 kW

Sealing size/number: 350mm /1

Classification:

Cutter, saw blade and other consumables

Weight

Stock surplus

隐藏域元素占位

Product Description

S.EU Brand Grindstone

The whetstone is also known as: stone/double-sided stone/slaughterhouse special grinding stone/woodworking grinding stone/household grinding stone

S.EU whetstone Features:

According to the size of the grindstone, it can be divided into coarse grindstone (generally below 1000 mesh) and fine grinding stone (above 2000 mesh).

S.EU monochrome grindstone size: 210*65*33 / 200*50*25 this is a special grindstone for slaughterhouses, which is a large size. The knife used in the slaughterhouse is a high-frequency knife, and the grinding stone is too small and too thin to be relatively wasteful (once the grinding stone breaks, it is scrapped). It is generally recommended that each worker choose two grindstones, one for rough grinding (about 1000 mesh is more appropriate, if the mesh is too low, the knife will be used) and one for fine grinding (more than 2000 mesh, if the mesh is too high, the knife will be saved, but the grinding speed will be slightly reduced).

S.EU double-color sharpening stone size: 180*60*30 / 200*50*25 This is a sharpening stone for family hotels. The recommended mesh number is 1000/3000

Color: white, yellow, gray

Note: According to customer needs, different mesh numbers and different sizes of sharpening stones (400-8000 mesh) can be selected, and monocular sharpening stones and binocular sharpening stones can also be selected.

Grindstone instructions

1. Before sharpening the knife, clean the knife with water so that there will be no impurities when grinding

2. Rinse the sharpening stone with water for a while, preferably soak in water for a while, and let the sharpening stone soak in water (about 10 minutes).

3, the sharpening stone flat, fixed ready to sharpen the knife.

4. When sharpening the knife, first grind the rough surface of the sharpening stone, and you can distinguish the rough surface and the fine surface of the sharpening stone by touching it with your hand. Rough surface rough grinding, fine surface fine grinding.

5. The knife and the sharpening stone are at an angle of about 17 degrees (the sharpening angle of different knives is slightly different, such as dividing knives, machetes, etc.), friction back and forth, and some water should be added during the friction to avoid excessive temperature of the knife edge. Note: the smaller the blade angle, the sharper the knife, the smaller the cutting resistance, the higher the sharpness, but the corresponding sharpness will be poor.

6. After grinding one side of the knife, grind the other side of the knife, and add some water in the middle (don't scrape off the mud from the grinding stone, the slurry water can sharpen the knife more sharply). After grinding both sides of the knife, change the fine side of the sharpening stone and carry out fine grinding (if it is a single-mesh sharpening stone, please replace a high-mesh sharpening stone). Fine grinding stone can make the rough blade become more smooth, sharp.

7. After grinding, rinse the knife and sharpening stone with clean water and put them away.

Key words:

- Product Description

-

- Commodity name: Special grindstone for slaughterhouse

S.EU Brand Grindstone

The whetstone is also known as: stone/double-sided stone/slaughterhouse special grinding stone/woodworking grinding stone/household grinding stone

S.EU whetstone Features:

According to the size of the grindstone, it can be divided into coarse grindstone (generally below 1000 mesh) and fine grinding stone (above 2000 mesh).

S.EU monochrome grindstone size: 210*65*33 / 200*50*25 this is a special grindstone for slaughterhouses, which is a large size. The knife used in the slaughterhouse is a high-frequency knife, and the grinding stone is too small and too thin to be relatively wasteful (once the grinding stone breaks, it is scrapped). It is generally recommended that each worker choose two grindstones, one for rough grinding (about 1000 mesh is more appropriate, if the mesh is too low, the knife will be used) and one for fine grinding (more than 2000 mesh, if the mesh is too high, the knife will be saved, but the grinding speed will be slightly reduced).

S.EU double-color sharpening stone size: 180*60*30 / 200*50*25 This is a sharpening stone for family hotels. The recommended mesh number is 1000/3000

Color: white, yellow, gray

Note: According to customer needs, different mesh numbers and different sizes of sharpening stones (400-8000 mesh) can be selected, and monocular sharpening stones and binocular sharpening stones can also be selected.

Grindstone instructions

1. Before sharpening the knife, clean the knife with water so that there will be no impurities when grinding

2. Rinse the sharpening stone with water for a while, preferably soak in water for a while, and let the sharpening stone soak in water (about 10 minutes).

3, the sharpening stone flat, fixed ready to sharpen the knife.

4. When sharpening the knife, first grind the rough surface of the sharpening stone, and you can distinguish the rough surface and the fine surface of the sharpening stone by touching it with your hand. Rough surface rough grinding, fine surface fine grinding.

5. The knife and the sharpening stone are at an angle of about 17 degrees (the sharpening angle of different knives is slightly different, such as dividing knives, machetes, etc.), friction back and forth, and some water should be added during the friction to avoid excessive temperature of the knife edge. Note: the smaller the blade angle, the sharper the knife, the smaller the cutting resistance, the higher the sharpness, but the corresponding sharpness will be poor.

6. After grinding one side of the knife, grind the other side of the knife, and add some water in the middle (don't scrape off the mud from the grinding stone, the slurry water can sharpen the knife more sharply). After grinding both sides of the knife, change the fine side of the sharpening stone and carry out fine grinding (if it is a single-mesh sharpening stone, please replace a high-mesh sharpening stone). Fine grinding stone can make the rough blade become more smooth, sharp.

7. After grinding, rinse the knife and sharpening stone with clean water and put them away.

Previous Page

Next Page

Related recommendations

Product Consulting

Provides you with a complete solution, ready for your choice